ROLLER LUBRICATION SYSTEMS, SPRAY LUBRICATION SYSTEMS, DISPENSER SOLUTIONS

LUBRICATION SYSTEMS

Millutensil produces roller, felt-covered (or brush), and spray lubrication systems.

Millutensil also produces dispenser systems, along with pressure and electronic feed systems.

- Lub. with felt rollers

- Roller lubricators with brushes

- Lub. with felt motorized rollers

- Lub. with felt rollers

- Lub. for lateral lubrication

- Lub. with quick felt change

- Three-section lubricators

- Section roller lubricators

- Lubrication system for panel

- Lubrication system for discs

- Spry lubricators

- Feed systems

- Aspiration systems

- Installations

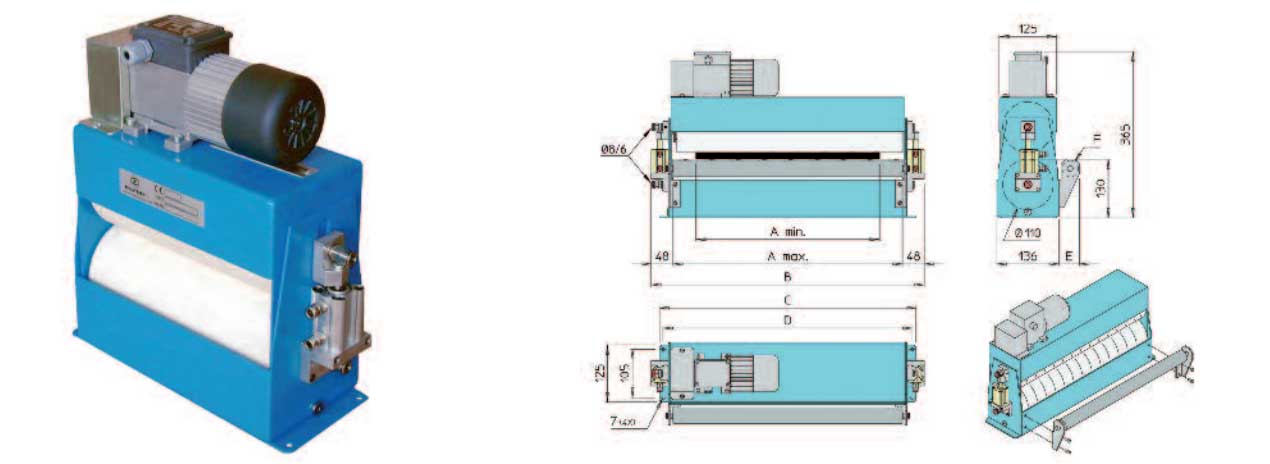

Felt covered rollers lubrication LRF 32 / 60 / 110

The oil is fed to the felt rollers from the inside-out, through the cavities.

The upper roller regulation on the material occurs by means of tension springs.

SPECIFICATION

| LRF 32 | LRF 60 | LRF110 | |

|---|---|---|---|

| Oil viscosity at 40° C | up to 100 mm2/s | up to 150 mm2/s | up to 200 mm2/s |

| Feeding length approx. | 100 mm | 180 mm | 200 mm |

| Stroke number | automatic speed presses | up to 150 per min. | up to 100 per min |

| Thickness of material | up to 1 mm | from 0,5 to 1,5 mm | from 1 to 5 mm |

| Sheet width | from 20 to 250 mm | from 80 to 800 mm | from 150 to 1.000 mm |

APPLICATION

- Suitable for blanking and bending operations

- In a limited way for drawing operations

Lubricators with brushes brushing rollers LRS 60

The oil is fed to the brush rollers from the inside-out, through the holes.

The upper roller regulation on the material occurs by means of tension springs.

SPECIFICATION

| LRS 60 | |

|---|---|

| Oil viscosity at 40° C | from 80 up to 250 mm2/s |

| Feeding length approx. | 180 mm |

| Stroke number | up to 120 per mm |

| Thickness of material | from 1 to 2 mm |

| Sheet width | from 80 to 430 mm |

APPLICATION

- Suitable for blanking, bending and drawing

Lubricators with felt motorized rollers LRFM 110

The oil is fed to the felt rollers from the inside-out, through the cavities. The upper roller regulation on the material occur by means of a pneumatic cylinder.

A gear-motor drives the upper roller at fixed speed.

On request, the upper roller can be supplied with an inverter variable speed drive.

SPECIFICATION

| LRFM 110 | |

|---|---|

| Oil viscosity at 40° C | up to 240 mm2/s |

| Feeding length approx. | Unlimited feeding length |

| Stroke number | up to 100 per mm |

| Thickness of material | max 10 mm |

| Stroke of upper roller | 15 mm |

| Sheet width | from 150 to 1.000 mm |

APPLICATION

- Suitable for blanking, bending and drawing

Lubricators with felt rollers LRFP 110

The oil is fed to the felt rollers from the inside-out, through the cavities. The upper roller regulation on the material occurs by means of a pneumatic cylinder.

SPECIFICATION

| LRFP 110 | |

|---|---|

| Oil viscosity at 40° C | up to 200 mm2/s |

| Feeding length approx. | Unlimited feeding length |

| Stroke number | up to 100 per mm |

| Thickness of material | from 1 to 8 mm |

| Stoke of upper roller | 15 mm |

| Sheet width | from 1.100 to 1.600 mm |

APPLICATION

- Suitable for blanking, bending and drawing

Lubricators with felt rollers for lateral lubrication LRFC 60

The oil is fed to the felt rollers from the inside-out, through the cavities. The upper roller regulation on the material occurs by means of pneumatic cylinder. The lubricators are usually positioned on the left and right side of the sheet to be lubricated.

SPECIFICATION

| LRFC 60 | |

|---|---|

| Oil viscosity at 40° C | up to 150 mm2/s |

| Feeding length approx. | 600 mm |

| Stroke number | up to 150 per mm |

| Thickness of material | 1 to 4 mm |

| Stroke of upper roller | 15 mm |

| Sheet width | from 100 to 200 mm |

APPLICATION

- Suitable for blanking, bending and drawing, forming machines

Roller lubricators with quick felt change LRFA 60

The oil is fed to the felt rollers fromthe inside-out, through the cavities.The upper roller regulation on the material occurs by means of tension springs. Felt-covered rollers can be quickly replaced using the release lever.

SPECIFICATION

| LRFA 60 | |

|---|---|

| Oil viscosity at 40° C | up to 150 mm2/s |

| Feeding length approx. | 600 mm |

| Stroke number | up to 150 per mm |

| Thickness of material | 1 to 4 mm |

| Stroke of upper roller | max 10 mm |

| Sheet width | from 100 to 1.000 mm |

APPLICATION

- Suitable for blanking, bending and drawing

Roller lubricators with quick felt change LRFAP 60

The oil is fed to the felt rollers fromthe inside-out, through the cavities.The upper roller regulation on the material occurs by means of pneumatic cylinder. Felt-covered rollers can be quickly replaced using the release lever.

SPECIFICATION

| LRAPF 60 | |

|---|---|

| Oil viscosity at 40° C | up to 150 mm2/s |

| Feeding length approx. | 600 mm |

| Stroke number | up to 150 per mm |

| Thickness of material | 1 to 4 mm |

| Stroke of upper roller | 10 mm |

| Sheet width | from 200 to 1000 mm |

APPLICATION

- Suitable for blanking, bending and drawing

Three-section lubricators with felt rollers LRF 110-3S

The oil is fed to the felt rollers fromthe inside-out, through the cavities.The upper roller regulation on the material occurs by means of pneumatic cylinder.

SPECIFICATION

| LRF 110-3S | |

|---|---|

| Oil viscosity at 40° C | up to 200 mm2/s |

| Feeding length approx. | Unlimited feeding length |

| Stroke number | up to 150 per mm |

| Thickness of material | 1 to 8 mm |

| Stroke of upper roller | 15 mm |

| Sheet width | from 800 to 1.800 mm |

APPLICATION

- Suitable for blanking, bending and drawing

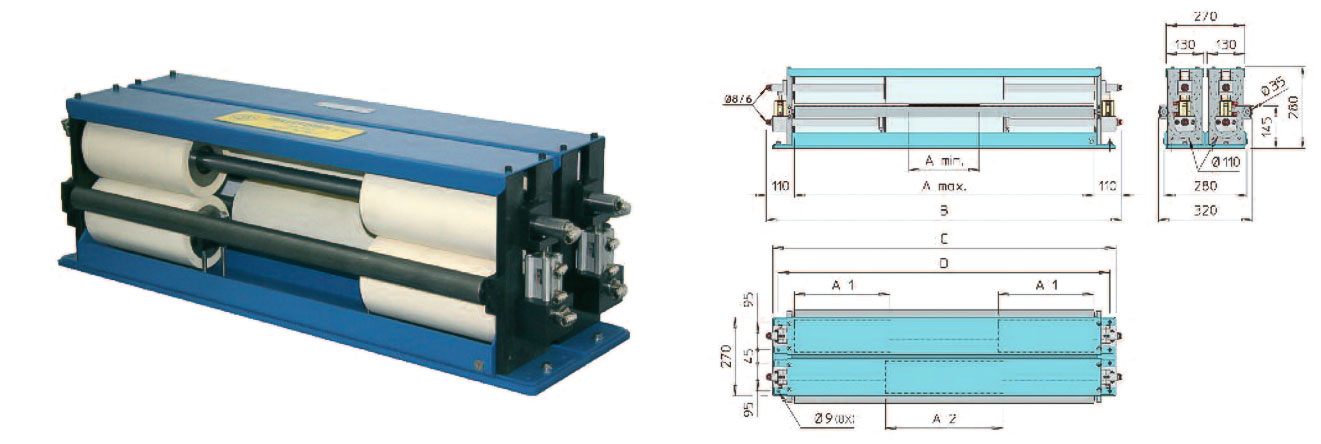

Section roller lubricators LRF2P 110 – LRS2P 110

The oil is fed to the rollers from the inside-out, through the cavities.

The upper and lower rollers regulation on the material occurs by means of pneumatic cylinders.

The lubricator can be equipped with an extractable tray system for easier maintenance.

SPECIFICATION

| LRF2P 110 – LRS2P 110 | |

|---|---|

| Oil viscosity at 40° C | up to 200 mm2/s |

| Feeding length approx. | Unlimited feeding length |

| Stroke number | up to 100 per mm |

| Thickness of material | 1 to 10 mm |

| Stroke of upper roller | 20 mm |

| Sheet width | from 200 to 2.150 mm |

APPLICATION

- Suitable for blanking, bending and drawing

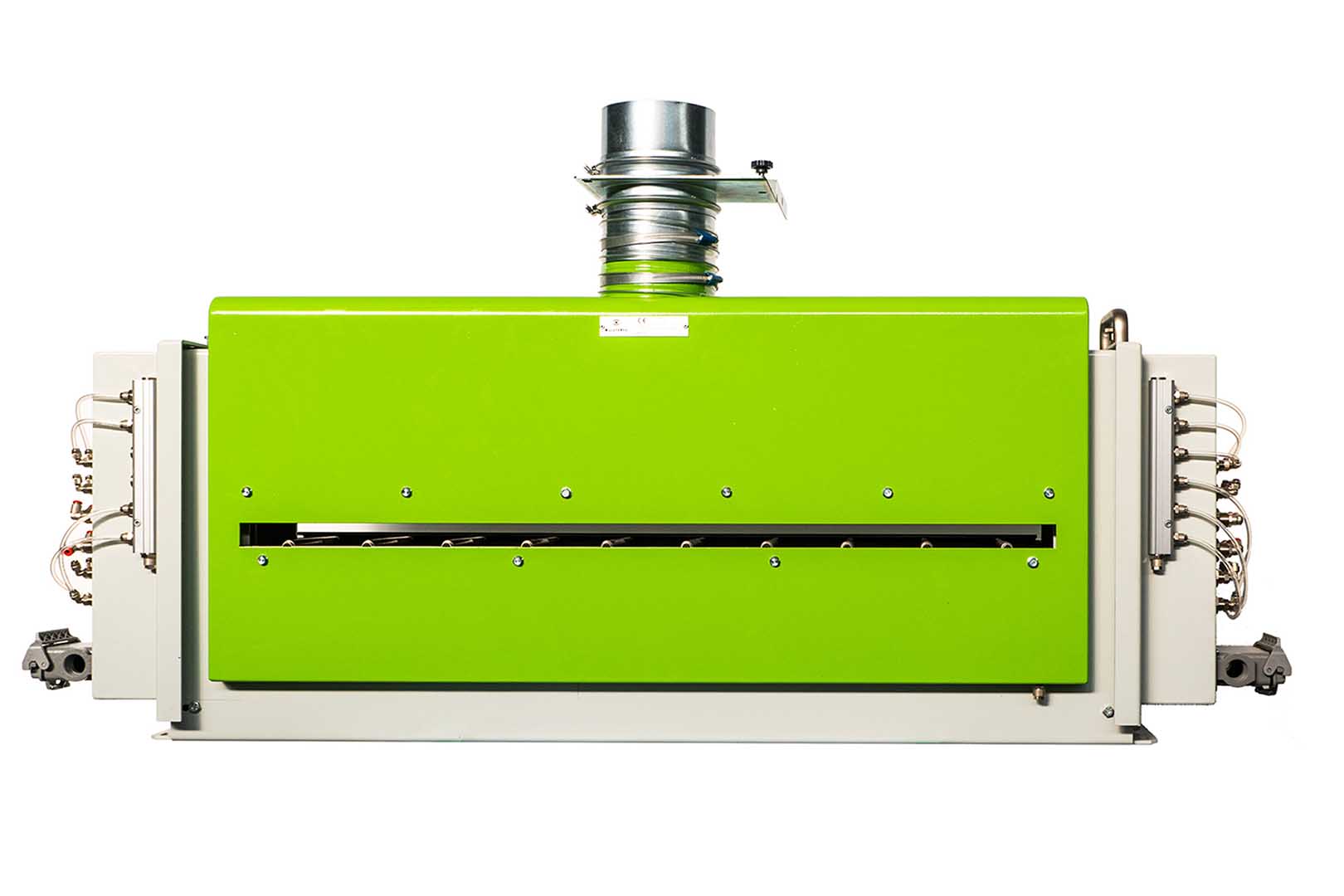

Lubricators system for panel

System built upon customer’s request according to the following parameters:

- Diameter of the motorized roller lubricator

- Pressurized oil dispensing system

- Plant box

- Electric control box

- Oil recovery container

- Oil collection tank

- Neutral rollers material input

- Motorized rollers material output

- Mechanical clamp for pieces stop

Lubrication systems for discs

System built upon customer’s request.

Request Roller Lubrication Systems

Spray Lubrication Systems Catalogue

Simply complete the form below and we'll send you our latest catalogue.